Last Updated: February 14, 2025

In Australia alone, hundreds of companies utilise industrial weighing solutions. This makes the present market highly competitive, and for newcomers, penetrating it may even be challenging. But that doesn’t mean it’s impossible to do. Regardless of the industry you operate in, if you focus heavily on accuracy and efficiency, you shouldn’t have issues running your enterprise smoothly. Note, though, that you can only achieve this by partnering with companies that offer smart weighing systems.

This blog will discuss the different industrial weighing solutions you can consider, their features, and how you can use them to streamline your operations and future-proof your business. But first, let’s discuss the basics.

How Important Are Accurate Weighing Systems?

Countless industries rely on accurate weighing systems to ensure quality in their operations. Some of the biggest players in logistics, manufacturing, mining, pharmaceuticals and agriculture make huge investments in industrial weighing scales. This is because they are necessary to ensure waste reduction, better inventory management, quality control and strict compliance with local and international regulations. The demand for these scales is continuously growing, and with the growing competition, it’s even more imperative for businesses to work with companies that offer the best industrial weighing options possible.

Inaccurate weighing systems can have significant financial repercussions. Overestimations or underestimations can lead to wasted materials, costly compliance fines, and even lost customers—all of which directly impact a company’s profitability. By investing in high-quality, accurate weighing systems, businesses safeguard their operations against these hidden costs and ensure they remain competitive in an increasingly demanding market. The right weighing solutions can make all the difference in maintaining efficiency and protecting the bottom line.

What Are the Most Common Types of Industrial Weighing Scales?

1. Platform Scales

Platform scales are used in various industrial applications. They have a flat platform surface on which goods can be placed for weighing. They are commonly used in warehouses, manufacturing plants, and shipping facilities to measure the weight of large items or bulk materials. Because these scales come in various sizes and capacities, they can be used in various applications, anywhere from weighing small parcels to larger machinery.

2. Freight Scales

Freight scales are indispensable in the shipping and logistics sectors and prevents discrepancies between declared and actual weight, which could eventually lead to financial losses or violations. Additionally, for companies that ship to their customers, dissatisfaction that can lead to complaints that can affect the business’s reputation is prevented. Freight scales can also be conveniently integrated into conveyor systems, which is another reason several businesses prefer them.

3. Weighbridges

Weighbridges are large vehicle weighing scales used to measure the weight of loaded and unloaded trucks. Several weighbridges for sale in Australia now come with more advanced and smart features like data recording, digital displays available locally or remotely and seamless management software integration.

4. Hopper Scales

Hopper scales are used in industries where bulk materials need to be weighed before processing. These scales consist of a hopper or container mounted on load cells, which measure the weight of the contents. Hopper scales are essential for weighing grains, powders, and other bulk materials in agriculture, food processing, and construction industries. They help ensure accurate batching and mixing processes, leading to consistent product quality.

Now that you’re familiar with some of the most common types of industrial scales, let’s help you decide which one is most appropriate for your business model.

Which Weighing System Does Your Business Need?

If it’s your first time buying industrial-grade weighing systems or your first time buying for a new line of business, here are some factors you need to consider.

Carefully Assess and Determine Your Needs

This is perhaps the most difficult thing you need to consider because it requires that you really take a good look at your business model so you can buy the right weighing equipment. You need to take note of the materials you handle, how much of it you process, and the allowable margin of error for the specific industry. You have to take into account any potential expansion you may have in the future so you don’t have to make a new purchase that better fits that new business.

Consider the Environment

Where will you be primarily using the scales, and in what manner? Do you need features like weather resistance, large displays, and waterproofing? Is the equipment going to be transported to a location with difficult access? How high or low does the temperature go in the work area? These are just some of the things that need to be considered before making an investment as big as this.

Budget

How much are you willing to spend on a weighing system? Have you checked the numbers and ROI details? Will your business benefit from automated weighing systems? Whatever model you decide on, it needs to give you the best balance between cost and functionality.

Implementing Smart Weighing Solutions

Once you’ve selected the right weighing system and precision weight measurement technology for your business, the next step is implementation. Here are some tips to ensure a smooth transition:

Training

Ensure that your staff is adequately trained to use the new weighing system. Proper training will maximise the system’s benefits and minimise errors.

Integration

Integrate the weighing system with your existing processes and software. This will streamline your operations and make your workflow more efficient and reliable.

Maintenance

Never take this step for granted. Just because your scales work fine doesn’t mean you can skip a maintenance schedule or two. Be strict about following the recommended maintenance frequency to address issues right away.

What Are the Latest Innovations in Industrial Weighing?

IoT-Enabled Weighing Systems

Internet of Things (IoT) integration makes real-time data sharing possible even across multiple devices and all simultaneously. These systems improve visibility and control over operations through remote monitoring.

Smart Calibration Technology

Removing the need for manual adjustments vastly enhances reliability in your operations, not to mention that it limits human error.

Data Integration and Analytics

Modern weighing solutions can now integrate with ERP (Enterprise Resource Planning) and supply chain management systems. Optimise your processes in real-time.

Wireless and Mobile Weighing Solutions

Allow your operators to perform on-the-go weighing no matter where they are even without physical access to your industrial weighing scales.

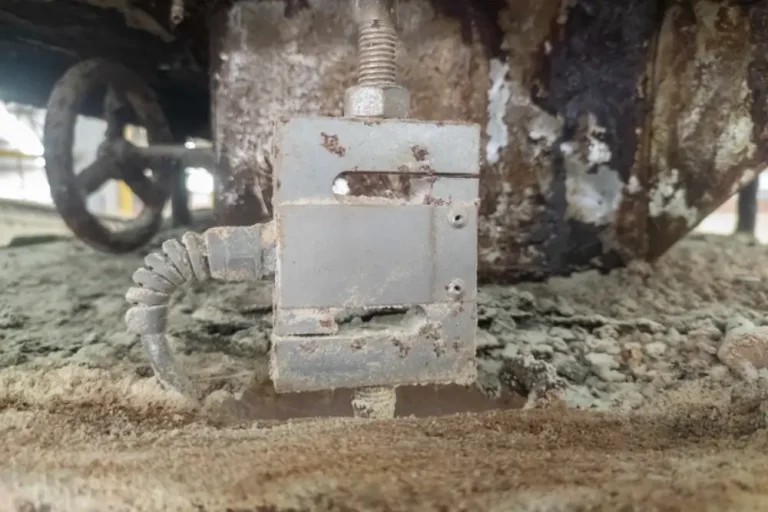

Advanced Load Cell Technology

Newer load cells have higher sensitivity and resistance to temperature fluctuations, improving measurement accuracy.

AI and Machine Learning Integration

Predict subtle trends and detect anomalies very early on to optimise processes, prevent errors, and improve decision-making based on historical data.

Future-Proof Your Business

Investing in smart and data-driven industrial solutions is a significant step towards future-proofing your business. These industrial-grade scales will allow you to compete even in a highly saturated market. Remember, at the end of the day, clients will take their business to companies with a reputation for quality and accuracy.

If you’re looking for your first or next industrial weighing scale, don’t hesitate to contact Hunter Weighing. We’re happy to assist you in finding the best weighing solutions for your business and take care of your repair, maintenance and calibration needs. Invest in accuracy and efficiency today so that you can enjoy profitability tomorrow.