Precision is everything when operating in sectors that rely on accuracy. No matter what industry you’re in, your choice of weighing technology will dictate how efficient, productive and safe your workspace will be. Despite this fact, several businesses continue to use outdated weighing equipment, not fully acknowledging the potential risks they’re exposing themselves to. If you’re a business owner, here are some of the problems you can avoid by staying away from outdated technology.

Incompatibility with Modern Systems

One of the most significant drawbacks of outdated industrial weighing scales is its incompatibility with modern systems. Most sectors now use integrated solutions where data from weighing scales are reflected in real time for use in inventory management or quality control systems. Obviously, older, manual scales do not have this capability which means data collection and reporting requires additional manpower. This lack of digital interfaces or connectivity options is not just an inconvenience, it also adds to operational costs.

If you’ve ever wondered if scales can be inaccurate due to outdated mechanisms, the answer is a resounding yes. Manual checking and monitoring are prone to human error and can have serious repercussions, especially in industries with strict compliance requirements.

Safety Hazards and Increased Liability

Outdated technology is inefficient. But in the grand scheme of things, the bigger problem would be that it’s unsafe. If you ever run into compliance issues because of inaccuracies, the worst thing you have to deal with will be fines or penalties. But if your equipment malfunctions and threatens the safety of your employees, it can lead to business closure and lawsuits.

Decreased Reliability and Accuracy

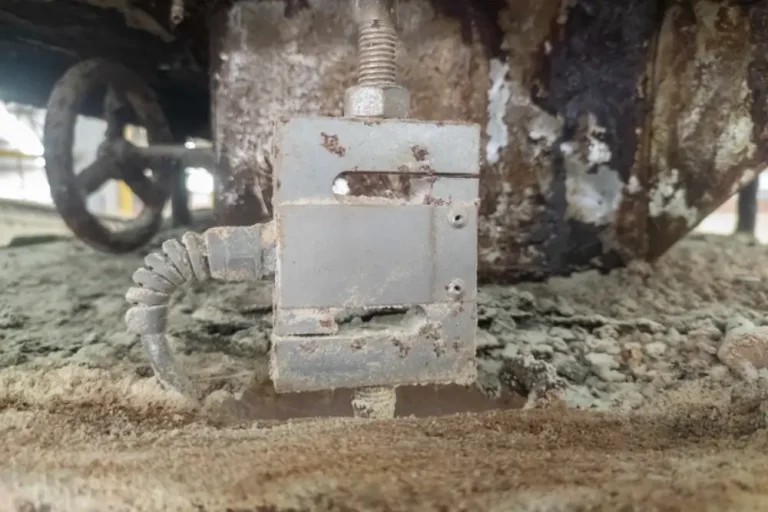

Of course, being digital doesn’t mean being accurate at all times. Even digital scales can be wrong if they’re not well maintained. As they age, some components will start to degrade, lubrication will dry up, certain parts exposed to moisture will rust. Eventually, this will result in fluctuating readings and unreliable performance that could cause product defects, packaging inconsistencies, improperly allocated materials or product recalls—problems that can cost your business its reputation.

Hindrance to Productivity and Innovation

Using antiquated weighing equipment restricts your capacity to develop and adjust to shifting market needs. Advanced features like automation, AI-driven insights, and IoT connectivity are built into newer systems to enable faster, more effective operations.

Businesses run the danger of slipping behind rivals who are using contemporary technology to stay ahead if they hang onto outdated equipment. Investing in innovative solutions not only increases output but also establishes your business as a leader in the field, ready to take on new challenges.

The Cost of Maintenance and Downtime

Older and more outdated weighing scales require frequent repairs and replacements – that’s just a fact. Even if you have a solid and comprehensive warranty, it will not cover the losses during downtimes. The more times your machines are out for servicing, the longer the disruptions at work and the bigger the financial impact. You never have to experience this inconvenience with more modern weight scales since they have been engineered with durability and ease of maintenance in mind.

Integrating industrial weighing hardware with advanced software can further reduce downtime by enabling predictive maintenance and automated alerts. Software solutions monitor the performance of your weighing equipment, detecting potential issues before they escalate. This proactive approach minimises unplanned servicing, ensuring your operations run smoothly with fewer interruptions. By investing in this combination, you not only cut maintenance costs but also enhance the longevity and reliability of your equipment.

Choosing the Right Industrial Weighing Scale Partner

Here at Hunter Weighing, we deliver state-of-the-art weighing solutions tailored to meet your unique needs. From belt weighers that enhance material flow accuracy to platform scales designed for heavy-duty applications, and weighbridges perfect for vehicle weighing, our comprehensive range of products supports businesses across various industries. We also offer silo and product weighers to optimise inventory management and electronic balances for precision weighing in day-to-day operations. We’re not just here to sell our products; we want to make sure you have all the information you need to make the right decision for your business.

From consultation to installation, we’ll ensure the whole transition process is as painless as possible for you and your team. To keep your systems performing at their best, we also provide scale calibration services, ensuring long-term accuracy and reliability. And even though we already provide state-of-the-art systems, we will still find a way to future-proof your operations with cutting-edge technology.

Our team of experts is dedicated to helping you maximise efficiency, accuracy, and safety with the latest weighing technology. Don’t let outdated equipment hold your business back—take the first step towards innovation today.

Invest in Updated Tech

Don’t let outdated weighing technology affect your business’s productivity and safety when there are several modern systems you can use that deliver unparalleled benefits. Whatever your reasons are for making the switch, know that it’s the best decision you can even make for your company. Contact us to learn more about our products and services and how we can partner for success.