In industrial operations, efficiency and accuracy are nonnegotiables. One of the key elements in maintaining this efficiency is reliable industrial weighing solutions. High-quality weighing systems, including electronic weighing machines and calibrated weighing scales, play a crucial role in various industrial processes. They ensure accuracy, prevent downtime, and ultimately, contribute to increased productivity.

Why Is Weight Calibration So Important?

Weight calibration is the process of verifying and adjusting the readings of a weighing scale. Regular calibration ensures that scales provide accurate weight measurements, which is crucial for quality control, regulatory compliance, and operational efficiency.

Consistency in Quality Control: Accurate measurements by calibrated weighing scales ensure that products meet quality standards. This is especially important in industries like pharmaceuticals, where precise ingredient measurements are crucial.

Regulatory Compliance: Many industries are governed by strict regulations that require accurate weight measurements. Regular weight calibration helps in adhering to these regulations, avoiding fines and legal issues.

Operational Efficiency: Correct weight scales reduce the risk of errors in product formulation, which can lead to the wastage of materials and time.

The indispensable role of weight calibration extends beyond maintaining standards; it’s about instilling a culture of precision across all operations. Engaging in regular calibration services ensures ongoing accuracy, fostering a proactive approach to quality and compliance. This not only minimises the risk of costly errors but also bolsters operational efficiency by streamlining processes and reducing downtime. It’s a strategic investment in the reliability and integrity of your measuring equipment. Thus, maintaining weighing accuracy through regular calibration services is foundational to achieving excellence in product quality, meeting regulatory demands, and enhancing overall operational productivity.

The Advantages of Electronic Weighing Machines

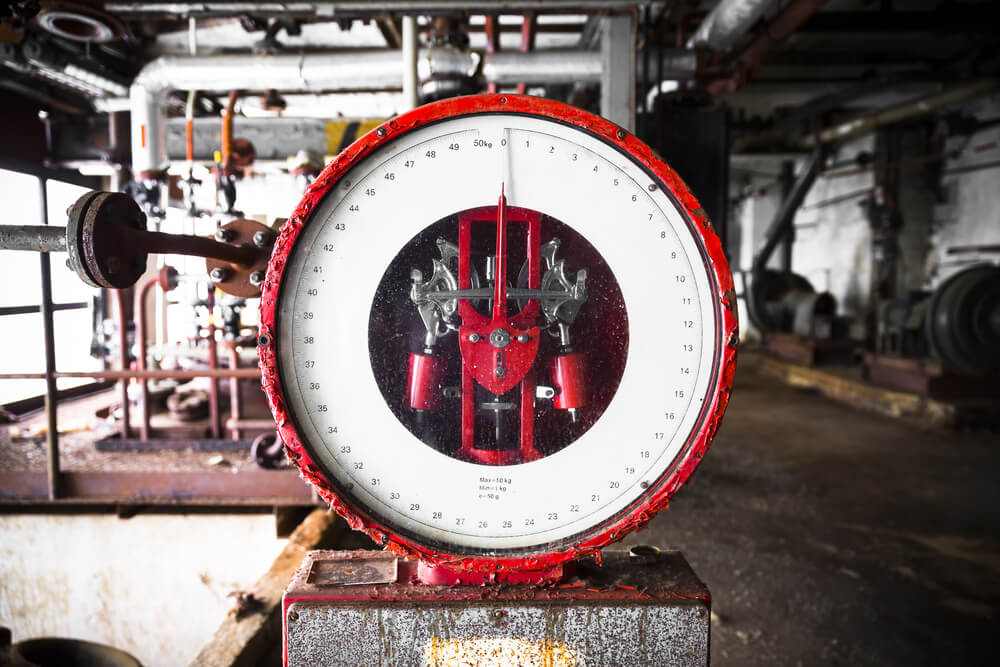

The introduction of electronic weighing machines has significantly transformed industrial weighing. Replacing traditional mechanical scales, these devices offer enhanced accuracy and a range of benefits that improve operations:

High Precision: Electronic weighing machines are known for their exactness. They offer more precise readings compared to their mechanical counterparts, which is crucial in industries where even the slightest deviation can have substantial consequences.

Ease of Use: One of the standout features of electronic scales is their user-friendly nature. Equipped with digital displays, these machines provide clear and immediate weight readings, eliminating the guesswork associated with reading analog scales. Their interfaces are typically straightforward, making them accessible to all users, irrespective of their technical expertise.

Enhanced Connectivity: Modern electronic weighing machines offer more than just weight measurements; they can be seamlessly integrated into broader IT infrastructures. This connectivity allows for automated data recording, reducing manual data entry errors and saving time. It also facilitates data analysis, providing valuable insights into operational efficiency, inventory management, and process optimisation.

Speed and Efficiency: Electronic scales streamline the weighing process, offering quick and accurate measurements. This speed is essential in high-volume environments like manufacturing and packing industries, where time efficiency directly impacts productivity.

Versatility and Customisation: These machines come in various sizes and capacities, suitable for different industrial needs. They can be customised with additional features like waterproofing for the food industry or rugged design for outdoor use, adding to their versatility.

Reduced Calibration and Maintenance: Electronic scales often require less frequent calibration and maintenance compared to mechanical scales. This not only reduces downtime but also cuts long-term operational costs.

Data Security and Management: Advanced electronic weighing machines often come with data security features, ensuring that the recorded information is protected. Additionally, their ability to connect with management systems allows for better inventory tracking and resource planning.

Investing in the Right Weigh Scales

When it comes to purchasing industrial scales, the right weight scales price is an important consideration. However, it’s equally crucial to consider the scale’s accuracy, durability, and suitability for your specific industrial needs.

Industry-Specific Features: Different industries have unique requirements. For example, scales used in the food industry might need to be waterproof and easy to clean.

Capacity and Durability: The scale should be able to handle the maximum expected load and withstand the environmental conditions of the workplace.

After-Sales Support: Reliable after-sales support and maintenance are crucial for the long-term functionality of the scales.

Work With Hunter Weighing for Industrial Weighing Services

Reliable industrial weighing services, like those provided by Hunter Weighing, are crucial for the efficient operation of various industries. By investing in high-quality electronic weighing machines and committing to regular weight calibration, businesses can substantially reduce downtime and enhance operational productivity.

At Hunter Weighing, we understand the importance of balancing the right weight scale price with long-term benefits and efficiencies. Our focus is on offering solutions that not only meet your immediate weighing needs but also contribute to the overall improvement of your industrial processes through superior accuracy and efficiency. Choose Hunter Weighing to take your industrial operations to new heights of precision and productivity.